EPCPROMAN

End to End Construction Management & Control Software Solution including Material Management & Detailed Construction Progress monitoring for all disciplines like :

- Piping

- Civil

- Structural

- Mechanical

- Electrical & Instrumentation

- HVAC

- Pre-Commissioning & Commissioning

EPC Software

EPCPROMAN is a meticulously designed Software solution developed by the team practically experienced in Construction Management of all disciplines in EPC Projects, focused on resolving practical pain areas in Construction Projects & adding value to projects by Time & Cost Saving with better grip/control on the Projects.

EPCPROMAN Solution is focused on Construction Management & Control, Material & Inventory Management, activity level construction progress updating at fabrication shops/erection sites.

Detailed level of Construction Progress monitoring & reporting to suit various hierarchical levels like Dashboards for Management Level, Consolidated Weekly & Monthly Progress Reports for Projects team, Material Inventory Status, Stock Register Reports for Materials Control team, Quality & Inspection Reports of Construction activities for Quality team etc.

Why Choose to Buy Construction Management Software?

EPCPROMAN provides great benefits to all the stake holders

- Owners

- EPCM (Engineering, Procurement, Construction) Management

- PMC (PROJECT MANAGEMENT CONSULTANT)

- LSTK / EPC CONTRACTORS

- CONSTRUCTION CONTRACTORS

- VENDORS / FABRICATORS

Why Do You Need EPCPROMAN ?

EPCPROMAN greatly improves the manual processes by automating them. Read below, how these processes are improved.

MTO-MR-PO-DELIVERY-ISSUE,

SHOPS-FIELDS-PROGRESS

(ALL ITEMS) MR-PO-EXPEDITING-DELIVERY-ISSUE-RETURN RECONCILIATION-HANDING OVER

MTO-MR-PO-DELIVERY-ISSUE-SHOPS-FIELDS-PROGRESS

MTO-MR-PO-DELIVERY-ISSUE-FIELDS-PROGRESS

MR-PO-DELIVERY-ISSUE-SHOPS-FIELDS-PROGRESS

MR-PO-DELIVERY-ISSUE-FIELDS-PROGRESS

EPCPROMAN Modules

Office Productivity Suite With Resource Assignment Analysis, Time Booking, File Tracking, To Do List, Calenders etc.

Electronic Document Management System – MDR/VDR, Approval Worflows & Transmittals, Commenting & Progress. Hold – Management/ Resolution/Tracking

Project Risk/Challenges Management System – Risk Register/Matrix/Heat Map/Chart/Profile/Mitigation/Reports. HSE Reports/Approvals/Audit

/Training/Team/Moment

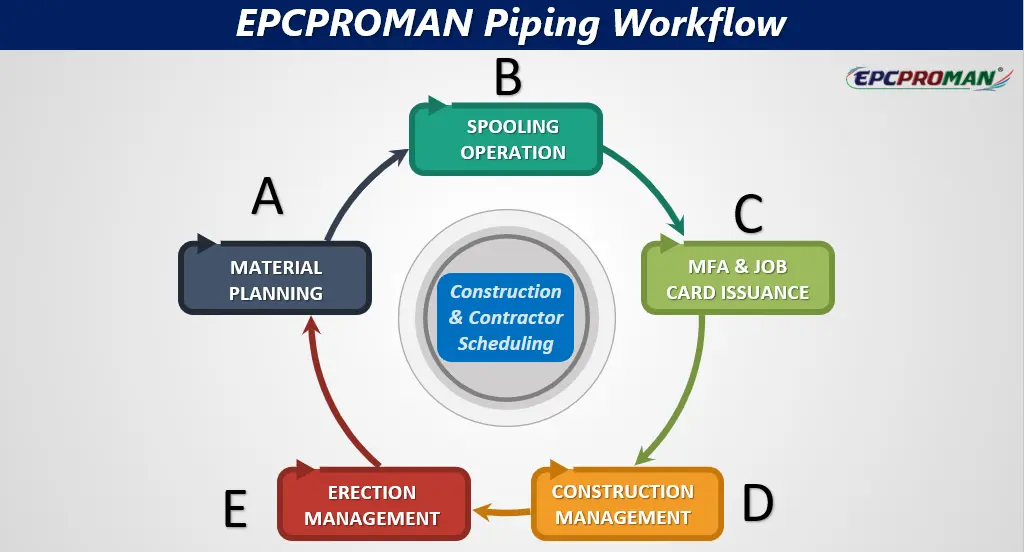

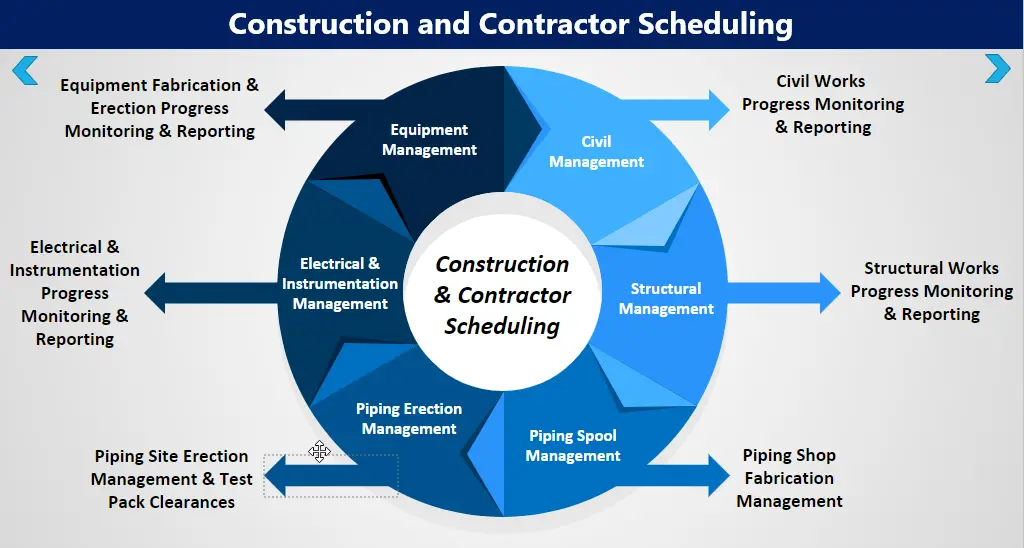

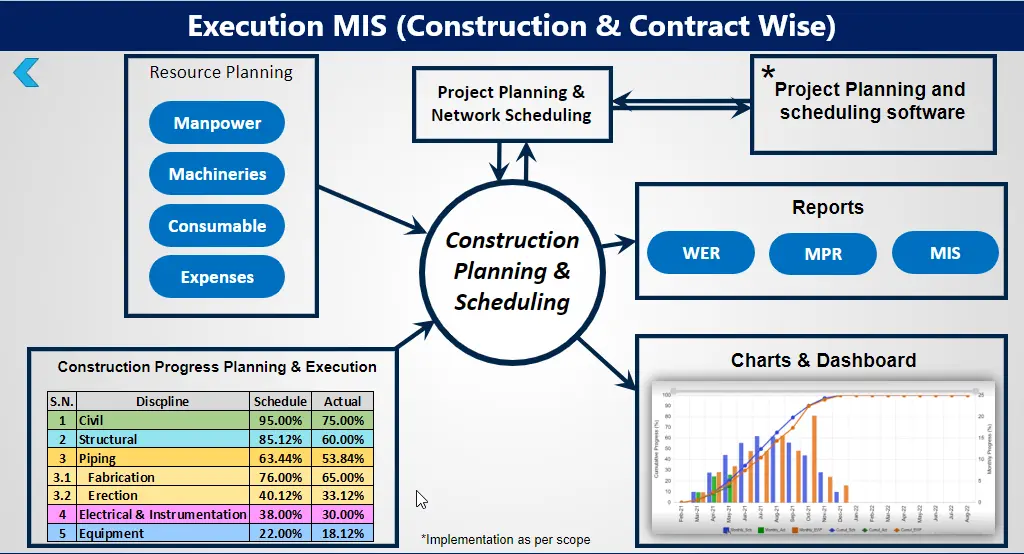

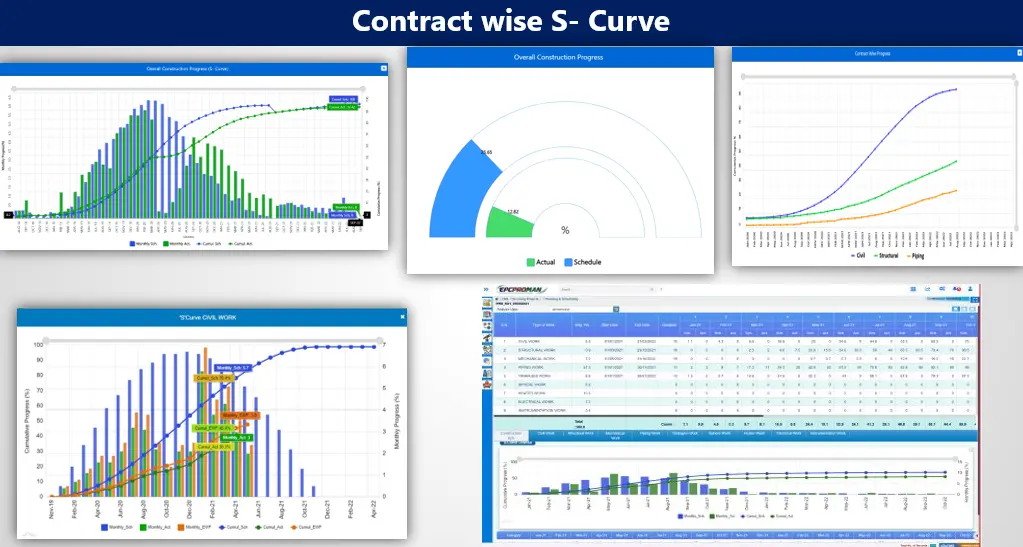

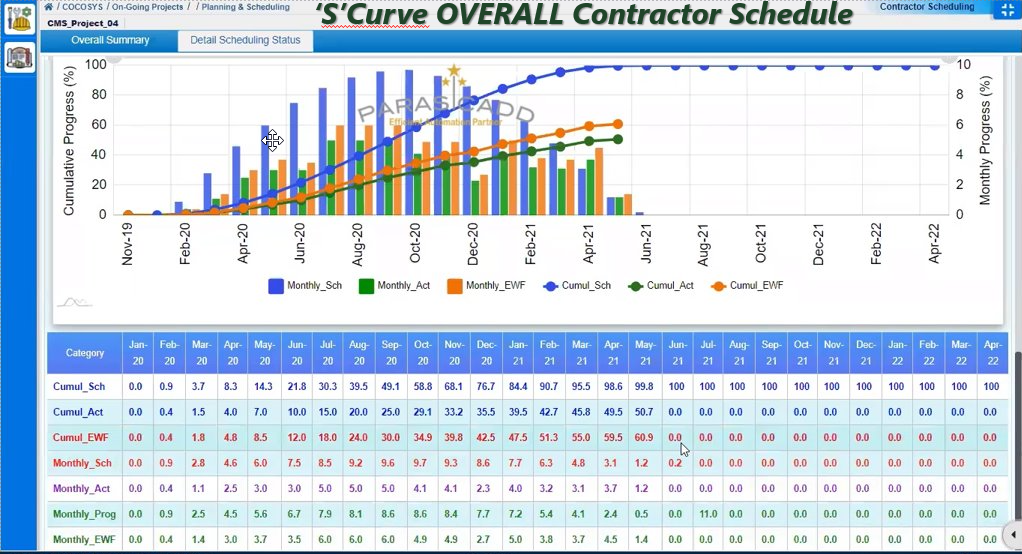

Construction & Contractor Scheduling – Contract Work items, Scope Qty distribution, Schedule/Actual Curves, Progress & Forecast

Automatic Piping Spooling – Fabrication Isometrics , Erection Isometrics with BOQ – Weld data – ID/IM – CutList etc.

EFA-MFA for Engineering Front Analysis & Material Front Analysis,

Indent for WHAM, Job Card

Piping Shop Fabrication Management. Piping Site Erection Management & Test Pack Clearances

Precommissioning & Commissioning Management – Turnover Packages – Systems/Sub-Systems MCC/CCC/SCC Certifications

Key Features & Benefits of EPC Software Suite

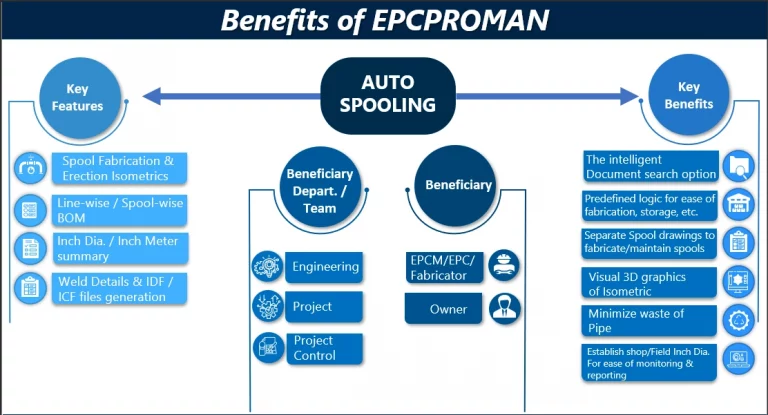

Piping spooling using AUTOSPOOL

Key Features

It provides Piping Spool Fabrication and Erection Isometrics, Line-wise / Spool-wise Bill of Materials, Inch Dia. / Inch Meter Summary, Weld details etc. from IDF / PCF files generated from 3D Modeling Software like PDMS, PDS, SP3D etc.

Key Benefits

- Easy of retrieving Isometrics due to single point location with intelligent search option

- Predefined logics based on ease of fabrication, storage, transportability and erection

- Minimize waste (unusable scraps) of Pipes due to predefined rule for cutting

- Optimum utilization of cut-pieces of Pipes

- Separate Spool drawings to fabricate / maintain Spools as inventory item

- Visual 3D graphics of Isometrics helps in proper decision for spool splitting

- Establish Shop / Field Inch Dia. for ease of monitoring and reporting

Beneficiary Department / Team

Engineering, Project, Project Control

Beneficiary Organisation

EPCM/EPC/Fabricator and finally Owner

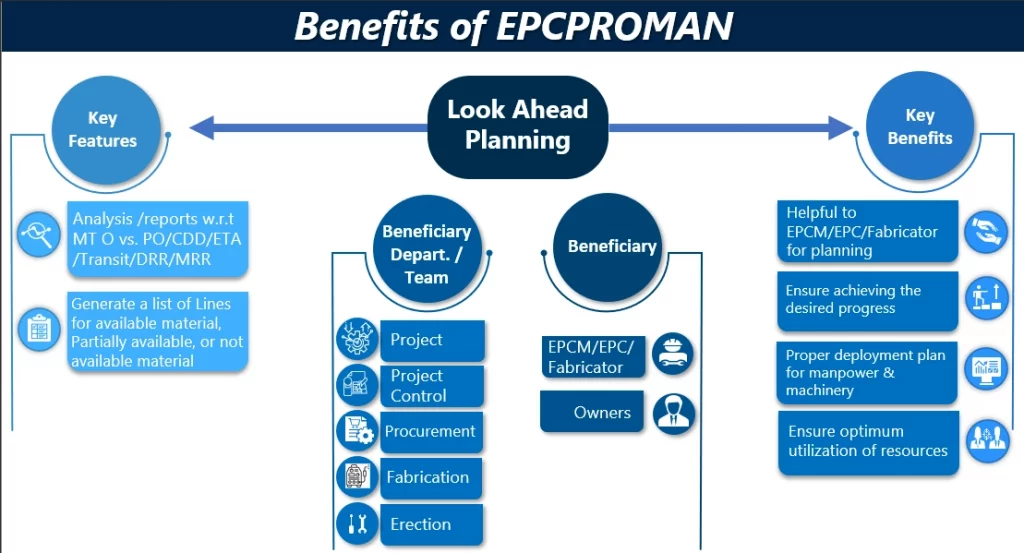

Material Look Ahead planning (based on engineering MTO)

Key Features

It provides analysis / reports w.r.t MTO vs. PO/CDD/ETA/Transit/DRR/MRR and generates list of lines for which materials are fully available. It also generates lists of lines for which materials are partially available or not available at all.

Key Benefits

- It will help EPCM/EPC/Fabricator to plan the work properly

- Ensure achieving desired progress

- Make proper deployment plan for manpower and machinery

- Ensure optimum utilization of resources

Beneficiary Department / Team

- Project, Project Control, Procurement, Fabrication, Erection

Beneficiary Organization

- EPCM/EPC/ Fabricator and finally Owner

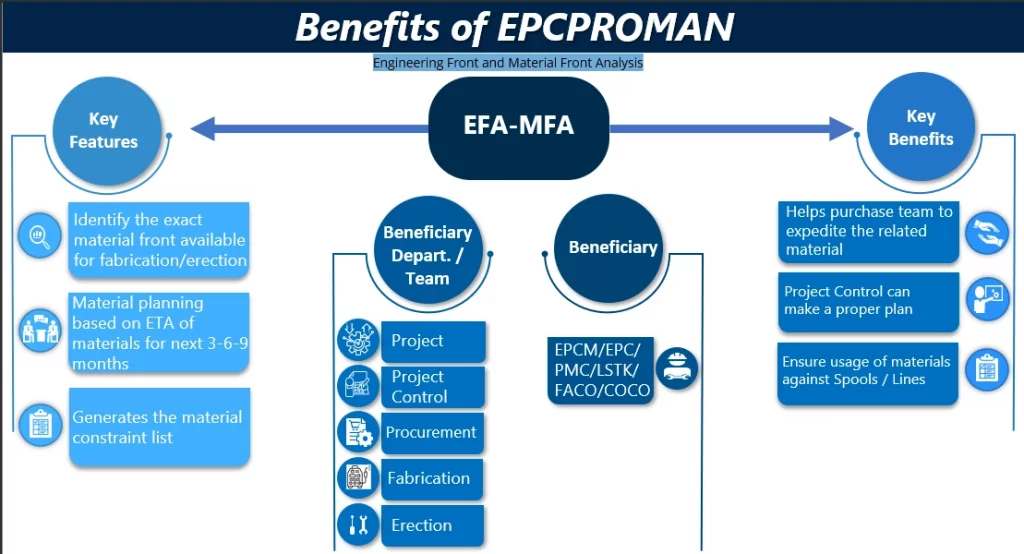

Material Front Analysis (MFA) for Fabrication and Erection work

Key Features

Identification of exact material front available for fabrication and erection work. Material planning can be done based on ETA of materials for next 3-6-9 months. Material constraint list can be generated.

Key Benefits

- Helps purchase team to expedite the related material procurement and delivery

- Project Control can make proper plan

- Ensure usage of materials against particular Spools / Lines

Beneficiary Department / Team

- Procurement, Project, Project Control, Fabrication, Erection

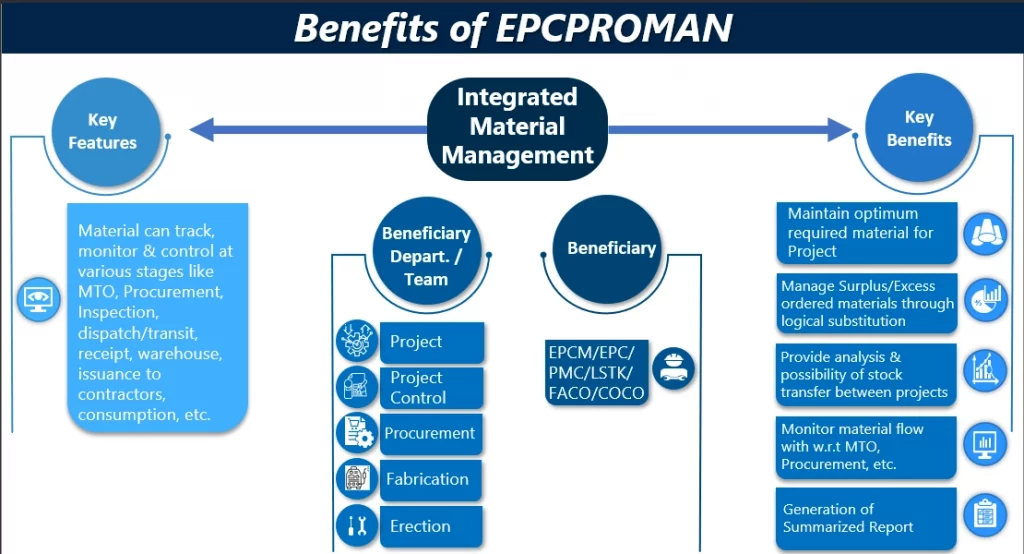

Integrated Material Management

Integrated Material Management w.r.t. MTO, PO, Shop and Store Quantities (inclusive of Consumption, Substitution, Transfer, Manufacturing and Reconciliation history)

Key Features

One can Track, Monitor and Control materials at various stages like MTO, Procurement, Inspection, Dispatch / Transit, Receipt, Storage location (Warehouse), Issuance to contractors, consumption, maintaining overhead / excess issued material, reconciliation of material.

Key Benefits

- Maintain optimum required material for the project.

- Avoid material shortfall / constraints.

- Avoid excess material purchase.

- Manage Surplus / Excess ordered materials through Logical Substitution.

- Provide analysis and possibility of Stock transfer between projects.

- Helps to track Free Issue materials and Procured materials.

- Monitor material flow with reference numbers and revision w.r.t MTO, Procurement, Receipt, Inspection, Consumption.

- Engineering MTO Analysis w.r.t Tender as well as AFC (Approved for Construction) quantities

- Generation of Summarized Report in Tabular Form for comparison of Tender, MTO and AFC Qty.

- Offload / Segregation / Reallocation of Scope in case of part work done by the Contractors

Beneficiary Department / Team

- Procurement, Project, Project Control, Construction

Beneficiary Organizations

- LSTK / EPC / EPCM / PMC / FACO / COCO

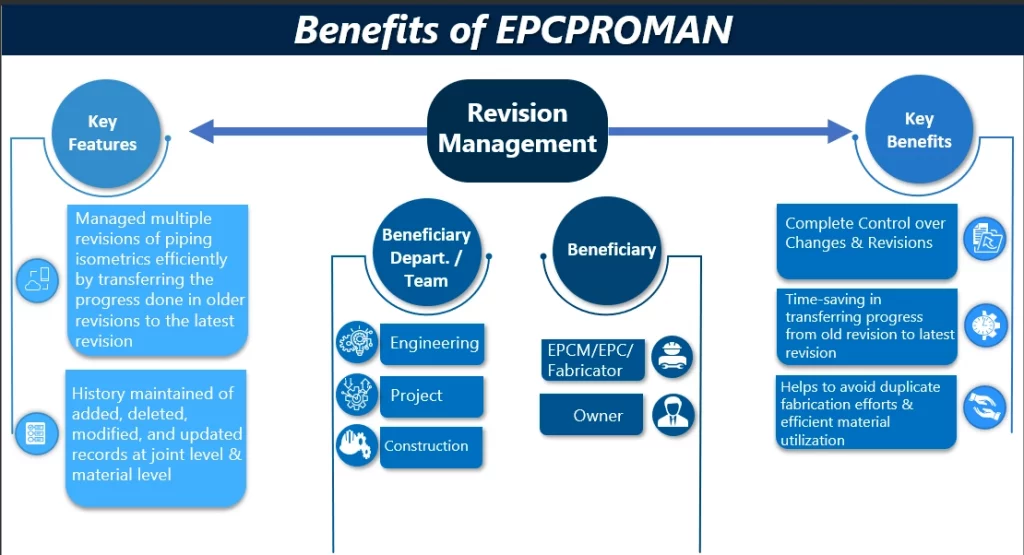

Revision Management of piping isometrics fabrication and erection work

Key Features

Multiple revisions of piping isometrics can be managed efficiently by transferring the progress done in older revisions to the latest revision in a controlled way. History of Added, deleted, modified, updated records at joint level and material level is maintained.

Key Benefits

- Complete Control over Changes and Revisions

- Time saving in transferring progress from old revision to latest revision

- Helps to avoid duplicate fabrication efforts and efficient material utilization.

Beneficiary Department / Team

- Engineering, Project, Construction

Beneficiary Organizations

- EPCM/EPC/Fabricator and finally Owner

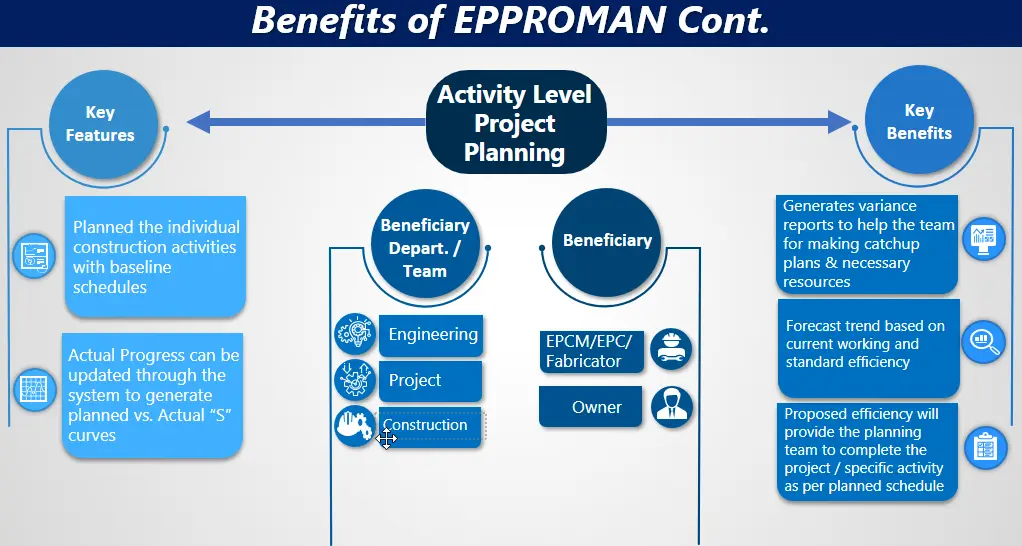

Activity level project panning, execution and progress updation reporting and monitoring

Key Features

Individual construction activities can be planned with Baseline Schedules and Actual Progress can be updated through the system to generate planned vs. Actual “S” Curves.

Key Benefits

- Variance report can be generated to help the team in making catchup plan and add necessary resources.

- Forecast trend based on current working efficiency and standard efficiency. Proposed efficiency will provide planning team to complete the project / specific activity as per planned schedule.

Beneficiary Department / Team

- Engineering, Procurement and Construction

Beneficiary Organization

- EPCM/EPC/PMC/Fabricator and finally Owner

Who should use EPCPROMAN ?

- Tender vs. MTO vs. AFC Qty. can be analyzed for calculating variance and take decision well in advance to manage the contracts properly.

- Combination of Qty. as well as Cost (Weightage terms of Effort & Cost) Reporting

- Risk Management has become part and parcel of Project Management. PROCHAL Module under EPCPROMAN identify Risks in various phases and suggest Suitable Mitigation Plans depending upon criticality of Risks.

- Planning, Scheduling, Monitoring & Reporting for Engineering, Procurement and Construction can be done using a single platform like EPCPROMAN.

- Resource loading both in terms of Qty. & Cost can be assigned against each Activity.

- Tender vs. MTO vs. AFC Qty. can be analyzed for calculating Variance and take decision well in advance to manage the contracts properly.

- Daily, Weekly and Monthly Progress Reporting can be done for each phase of project execution using only single platform.

- All types of Materials Management is possible (MTO-MR-PO-Delivery-Issue etc.)

- Piping Materials Management issued to the Contractors is made simple.

- Generation of Surplus Bulk Piping Materials can be reduced to maximum extent using Auto-Substitution feature of the system.

- In case of Offloading of certain portion of Contracts, scope can be segregated very easy and with clarity.

Some of the LSTK / EPC Contractors do have Standard / in-house Systems, however, they are not integrated, leading to mismatches at various stages of project execution. Moreover, there is understanding issues among the OWNER, PMC & LSTK / EPC Contractors in approach towards effective Project Control. It is always desirable to have one common platform like EPCPROMAN wherein integrated way of Planning, Scheduling, Monitoring and Reporting will be extremely beneficial for all the stakeholders.

EPCPROMAN addresses all the issues related to;

- Materials Management using Barcoding / RFID. This is the need of the hour to meet extremely tight schedule maintaining high Quality.

- Features like MTO Analysis, Item Codifications and Offloading of Scope are most important for LSTK / EPC Contractors.

- Helps in preparation of Invoices. Approval time for Invoices will be drastically reduced, which is so critical for flow of fund and maintain the work progress.

- Since, most of the Construction Contractors do not have proper system particularly for Piping Materials Management (both Supply and Execution) and Progress Calculation, they depend on EPCM. Hence, most of the time there is dispute in status of the job.

- For common understanding / status of the job, one integrated common platform is necessary to avoid conflict during execution of work.

- Construction Contractors should have robust Piping Materials Management System which will take care of all the logistics after issue of materials from the Owner’s Warehouse and issue of the same to their Sub-contractors, consumption and reconciliation thereof. Reconciliation is a very big issue.

- It has been observed that almost all the Contractors use to manage Piping Materials and Fabrication & erection activities using Excel Sheet. It is not at all desirable because of authenticity of data. As a result Total Scope of work and Actual progress do not match.

- Besides, Modules related to Piping work, the Construction Contractors should have Modules like CIVILMAN, STRUCTMAN, EQUIPMAN, Elect./Inst. for proper Planning, Progress Calculation and Progress Monitoring at Sites.

- It will also help in preparation of Invoices. Approval time for Invoices will be drastically reduced, which so critical for flow of fund and maintain the work progress.

- Since, Vendors / Fabricators obtain PO data with Specs. from the OWNER or EPCM, it is important that relevant Piping Modules of EPCPROMAN be used to facilitate activities in their Fabrication Shop.

- EPCPROMAN will help in Planning, Tracking, Monitoring and Reporting of fabrication activities and will also help in Progress Calculation which is so important in Overall Progress Calculation of the Project. Presently, it is missing a lot.

- EPCPROMAN will help in effective utilization of resources in Fabrication Shops.

- EPCPROMAN will also help in preparation of Invoices for timely payment.

Benefits of EPCPROMAN

- Integrated Material Management with respect to MTO, POs, Shops, Store, Fields (including Consumptions & Reconciliations)

- Material Front Analysis (MFA) for Fabrication and Erection work

- Look Ahead Planning for Spool Fabrication and Erection work

- Revision Management of Piping Isometrics for Fabrication and Erection work

- Activity level project planning, execution and progress updation reporting and monitoring

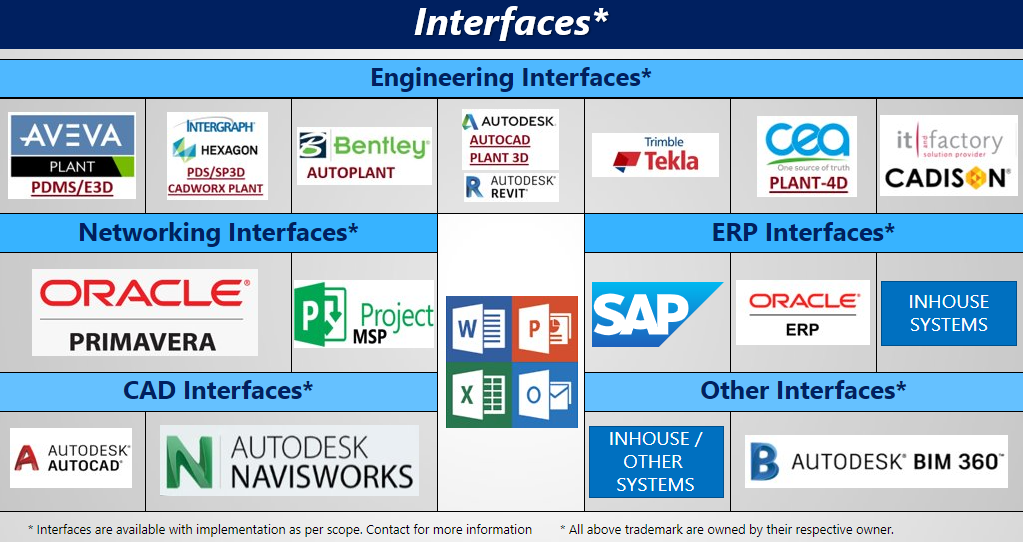

- Easy Integration with all the existing processes and standard practices in construction industry

- Easy Integration with in-house standardized software

- Best practices of all leading construction industries are available in the software.

project management software tools

EPCPROMAN is a epc software widely use in sectors such as Oil and Gas, Petrochemicals, Manufacturing & Construction, etc. for project control and management EPC Construction and EPC Construction EPC Construction EPC Construction

EPCPROMAN Features

Read About Features of EPCPROMAN.

Piping SPOOLING Automation

Key Features

It provides Piping Spool Fabrication and Erection Isometrics, Line-wise / Spool-wise Bill of Materials, Inch Dia. / Inch Meter Summary, Weld details etc. from IDF / PCF files generated from 3D Modeling Software like PDMS, PDS, SP3D etc.

- Easy of retrieving Isometrics due to single point location with intelligent search option

- Predefined logics based on ease of fabrication, storage, transportability and erection

- Minimize waste (unusable scraps) of Pipes due to predefined rule for cutting

- Optimum utilization of cut-pieces of Pipes

- Separate Spool drawings to fabricate / maintain Spools as inventory item

- Visual 3D graphics of Isometrics helps in proper decision for spool splitting

- Establish Shop / Field Inch Dia. for ease of monitoring and reporting

Beneficiary Department / Team

Engineering, Project, Project Control

Beneficiary Organisation

EPCM/EPC/Fabricator and finally Owner

Look Ahead Planning

Key Features

It provides analysis / reports w.r.t MTO vs. PO/CDD/ETA/Transit/DRR/MRR and generates list of lines for which materials are fully available. It also generates lists of lines for which materials are partially available or not available at all.

Key Benefits

It will help EPCM/EPC/Fabricator to plan the work properly Ensure achieving desired progress Make proper deployment plan for manpower and machinery Ensure optimum utilization of resources

Beneficiary Department / Team

Project, Project Control, Procurement, Fabrication, Erection

Beneficiary Organization

EPCM/EPC/ Fabricator and finally Owner

MFA For Fabrication & erection

Key Features

Identification of exact material front available for fabrication and erection work. Material planning can be done based on ETA of materials for next 3-6-9 months. Material constraint list can be generated.

- Helps purchase team to expedite the related material procurement and delivery

- Project Control can make proper plan

- Ensure usage of materials against particular Spools / Lines

Beneficiary Department / Team

Procurement, Project, Project Control, Fabrication, Erection

Integrated Material Management

Integrated Material Management w.r.t. MTO, PO, Shop and Store Quantities (inclusive of Consumption, Substitution, Transfer, Manufacturing and Reconciliation history)

Key Features

One can Track, Monitor and Control materials at various stages like MTO, Procurement, Inspection, Dispatch / Transit, Receipt, Storage location (Warehouse), Issuance to contractors, consumption, maintaining overhead / excess issued material, reconciliation of material.

- Maintain optimum required material for the project.

- Avoid material shortfall / constraints.

- Avoid excess material purchase.

- Manage Surplus / Excess ordered materials through Logical Substitution.

- Provide analysis and possibility of Stock transfer between projects.

- Helps to track Free Issue materials and Procured materials.

- Monitor material flow with reference numbers and revision w.r.t MTO, Procurement, Receipt, Inspection, Consumption.

- Engineering MTO Analysis w.r.t Tender as well as AFC (Approved for Construction) quantities

- Generation of Summarized Report in Tabular Form for comparison of Tender, MTO and AFC Qty.

- Offload / Segregation / Reallocation of Scope in case of part work done by the Contractors

Beneficiary Department / Team

Procurement, Project, Project Control, Construction

Beneficiary Organizations

LSTK / EPC / EPCM / PMC / FACO / COCO

Revision Management of Piping Isometrics

Key Features

Multiple revisions of piping isometrics can be managed efficiently by transferring the progress done in older revisions to the latest revision in a controlled way. History of Added, deleted, modified, updated records at joint level and material level is maintained.

- Complete Control over Changes and Revisions

- Time saving in transferring progress from old revision to latest revision

- Helps to avoid duplicate fabrication efforts and efficient material utilization

Beneficiary Department / Team

Engineering, Project, Construction

Beneficiary Organizations

EPCM/EPC/Fabricator and finally Owner

Activity Level Planning

Key Features

Individual construction activities can be planned with Baseline Schedules and Actual Progress can be updated through the system to generate planned vs. Actual “S” Curves.

Key Benefits

Variance report can be generated to help the team in making catchup plan and add necessary resources.

Forecast trend based on current working efficiency and standard efficiency. Proposed efficiency will provide planning team to complete the project / specific activity as per planned schedule.

Beneficiary Department / Team

Engineering, Procurement and Construction

Beneficiary Organization

EPCM/EPC/PMC/Fabricator and finally Owner