Asset Management with RFID and Barcodes

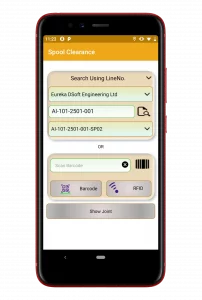

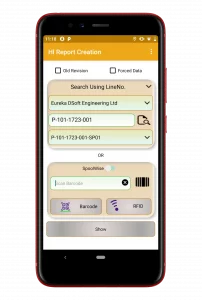

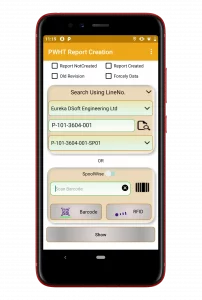

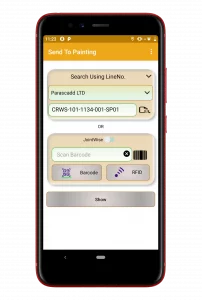

TRACK N TRACING App is an EPC Asset Management solution, which can help EPC companies to maintain the records of inventory. In Oil and Gas industry spools and erection components used for fabrication and erection of spools. TRACK N TRACING EPC Asset Management uses RFID, Bar-code & QR Code technologies with the best RFID, Bar-code readers integrated with the TRACK N TRACING mobile app.

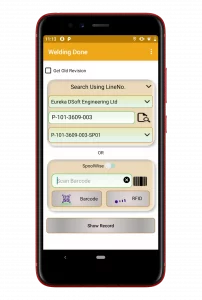

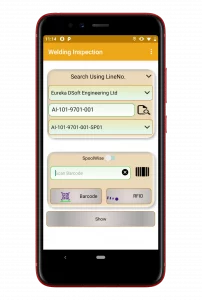

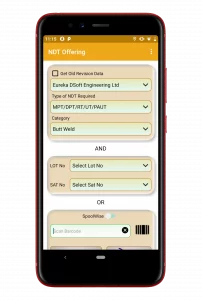

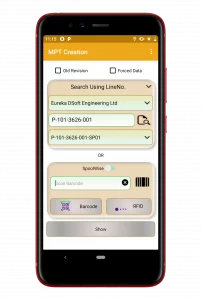

Process Automation Solution Using Barcodes and RFID technology on mobile apps through Online / Offline mode on the construction activity progress, manufacturing progress at vendor site and material dispatch and tracking along with asset search options.

This TRACK N TRACING mobile app synchronizes the material inventory to EPCPROMAN suite applications via the Wi-Fi, Cellular Network connection. It can also store data locally on the mobile device when offline and sync it to EPCPROMAN as soon as the network is found.

Key Features of TRACK-N-TRACING

- RFID, barcode, and QR code integration for seamless asset tracking

- Online/offline functionality for continuous data capture

- Real-time synchronization with EPCPROMAN suite applications

- Comprehensive asset search options for quick retrieval

- Mobile app for on-site data collection and management

Benefits of TRACK-N-TRACING

- Enhanced asset visibility and control

- Improved inventory accuracy and efficiency

- Reduced asset losses and misplacements

- Streamlined material dispatch and tracking

- Spool Tracking, Spool Search

- Tracking and Tracing RFID Generate RFID Tag ID for each spool data

- Attach the RFID Tag on the spool

- Store the spool at desired laydown area

- Go to laydown with hand held RFID Reader (Scan Range up to 4 to 15 meter)

- Scan hard RFID tag applied on assets by RFID reader

- Key-In location information

- TRACK-N-TRACING Software will update that information of assets to a database system

- Asset information can be found by login into the system

- Repeat above process if asset gets relocated.

Material Tracking using RFID

TRACK-N-TRACING Brochure

Discover How T-N-T Enhances Inventory Management using RFID, Barcode, and Mobile Application Solutions

How TRACK-N-TRACING Works

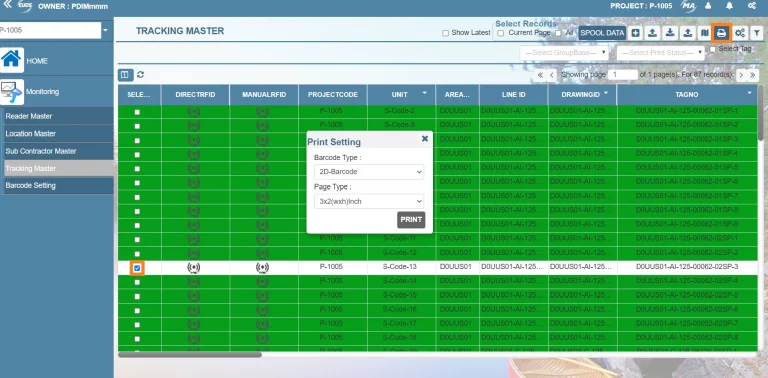

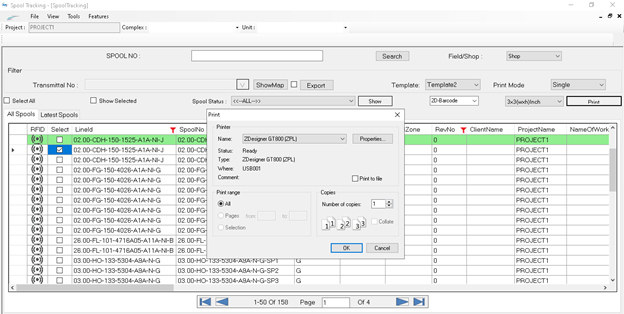

Generate & Print Barcodes

Attach the Tag

Scan and Update Location

Scan and Seach Location

Receive Dispatch by Scanning Voucher

Track on Map

Spool Tracking & Spool Search

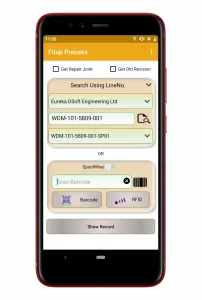

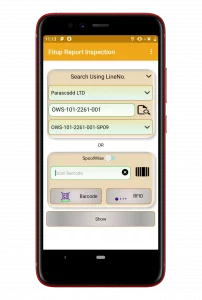

- Spool tracking & Spool search is done using Barcode scanning and RFID reader.

- The benefit of spool tracking & spool search is to keep track of spools, material inventory.

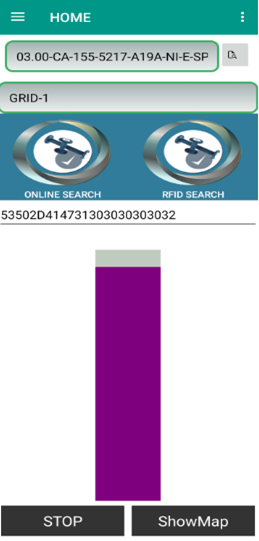

- For e.g. In a lay-down area N-number of spools are present and for a specific task we only need certain amount of spools so in that case with the help of RFID reader we have to enter the spool no & start the scanning process and eventually when we are near that spool will be getting an indication on the reader about the same.

- For tracking and searching of spools & materials we have Spool tracking, Spool search, Material tracking, Filter tracker, Welder tracker.

- Spool search: –When you select a spool with RFID reader and start scanning and as soon as you are near that spool the meter (as shown above) starts rising indicating how close you are to that spool

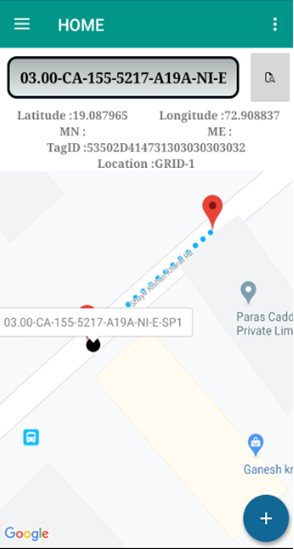

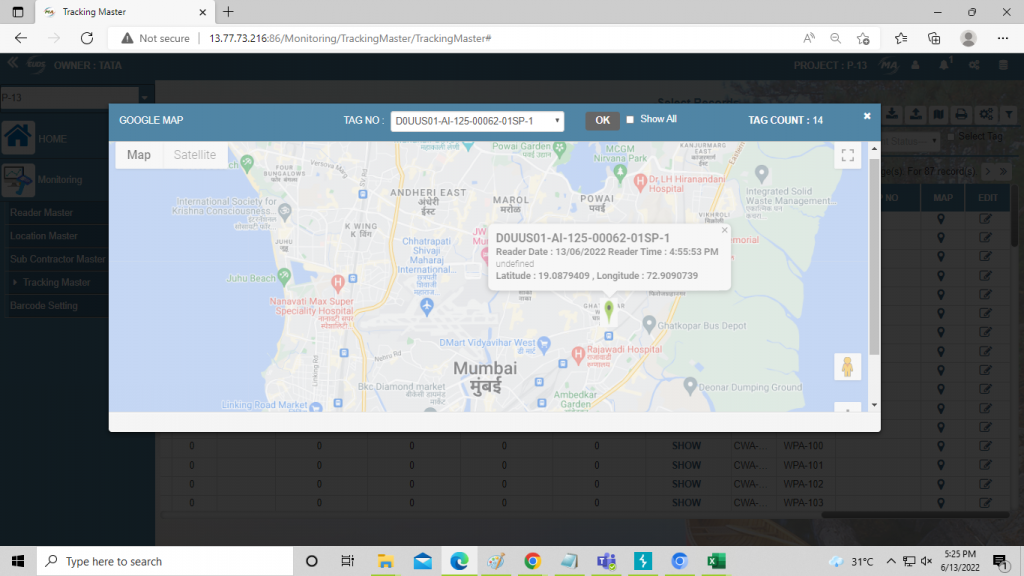

Show Map:-This map shows the distance between our live location and the current location of the spool on TNT mobile application.

SPOOLMAN Integration

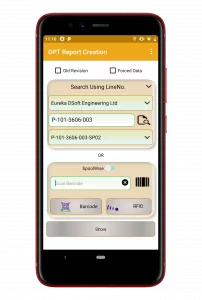

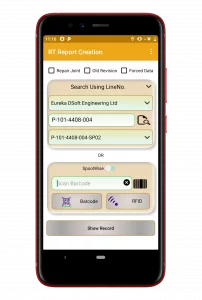

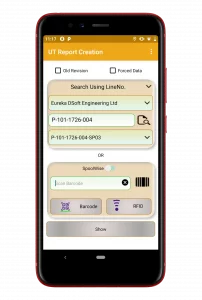

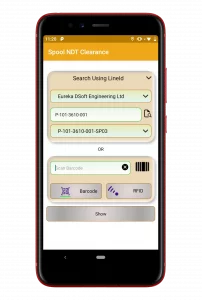

NDT (Non-Destructive-Testing)

It is a testing and analysis technique used to evaluate the properties of a material, component, for welding defects and discontinuities without causing damage to the original part.

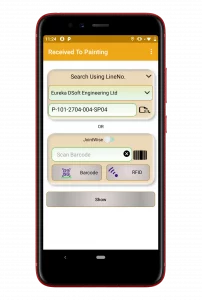

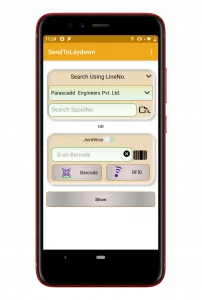

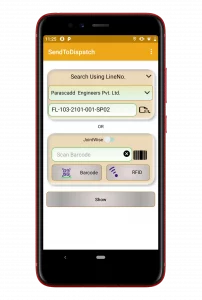

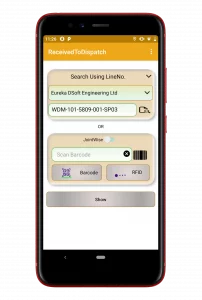

OGP (Outward Gate pass)

Modules such as Painting, Laydown, and Dispatch are present under outward gate pass.

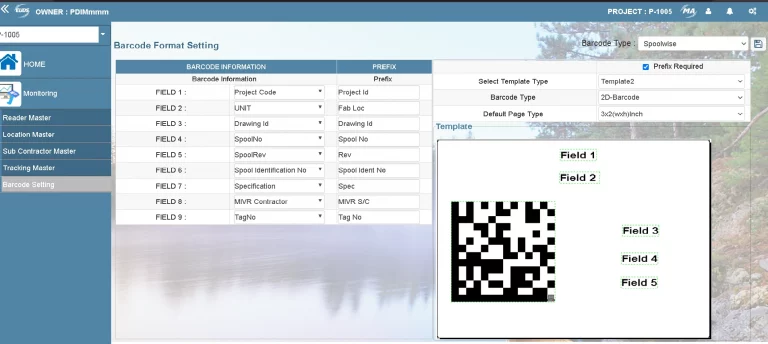

Barcode printing software facility in EPCPROMAN

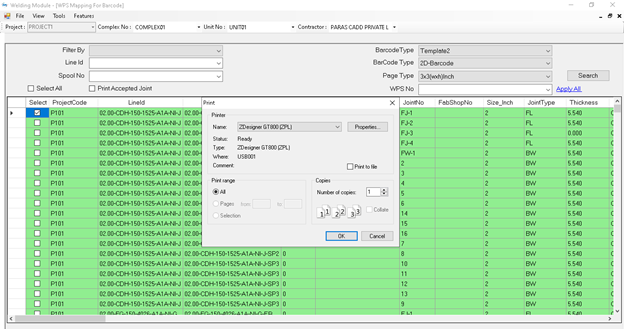

JOINT BARCODE

- For generating Joint barcode this feature is available in SPOOLMAN( EPCPROMAN SUITE ) ‘WELDING’ Module.

- Spool Barcode And Joint barcode is used for Progressing as well as Tracking location of all feature that is available in EPCPROMAN TNT Mobile application/ RFID Barcode.

- Item Barcode is Used for Tracking Heat No during fit-up time.

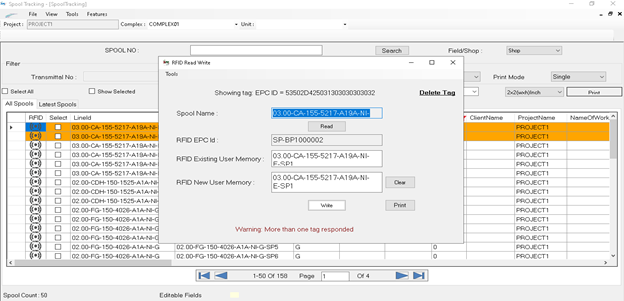

RFID read/write software facility in EPCPROMAN

- RFID Tags are used for tracking of the spool.

- Can also be viewed in Google Maps for location viewing with respect to scan time and scan date as shown below

Manage Inventory by using Barcode rfid tracking. How RFID Asset Tracking System Work?

Track N Tracking using Barcode, RFID, Inventory tracking , Asset management , Mobile app for Material, Fabrication and Erection actibity of EPCPROMAN. Inventory Tracking using Barcode, RFID, Inventory tracking , Asset management , Mobile app for Material, Fabrication and Erection .An RFID asset tracking system uses electromagnetic fields to transmit data from an RFID tag to a reader.